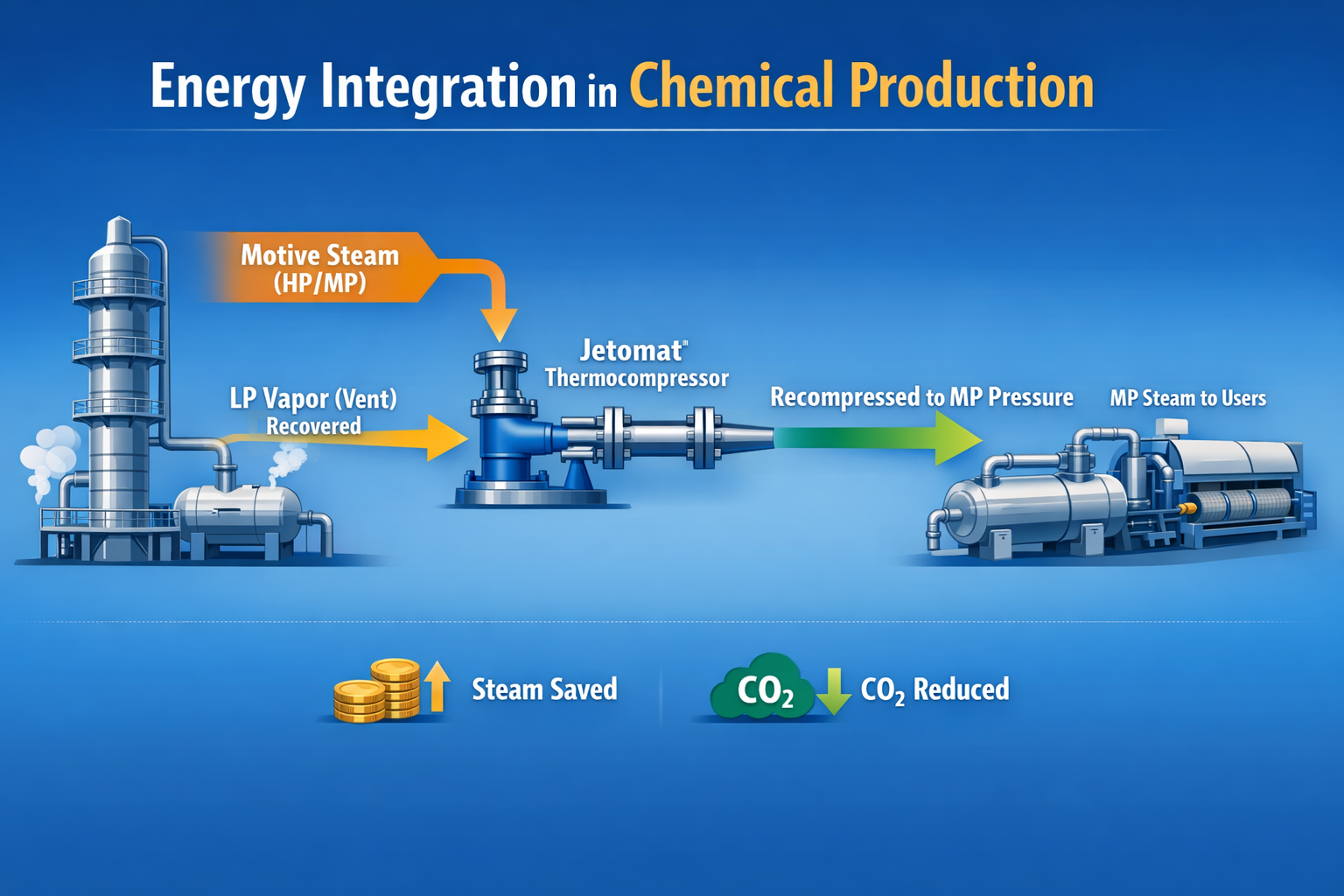

Energy Integration in Chemical Production

Jetomat enables energy integration in chemical plants by recompressing low-pressure waste vapor (from column vents/flash steam) using a small amount of high-pressure motive steam, then supplying that mixed steam to medium-pressure users like reboilers and dryers.

This converts vent losses into usable heat, typically cutting boiler steam/fuel, reducing CO₂ and visible plumes, and improving pressure/temperature stability with low maintenance since there are no rotating parts.

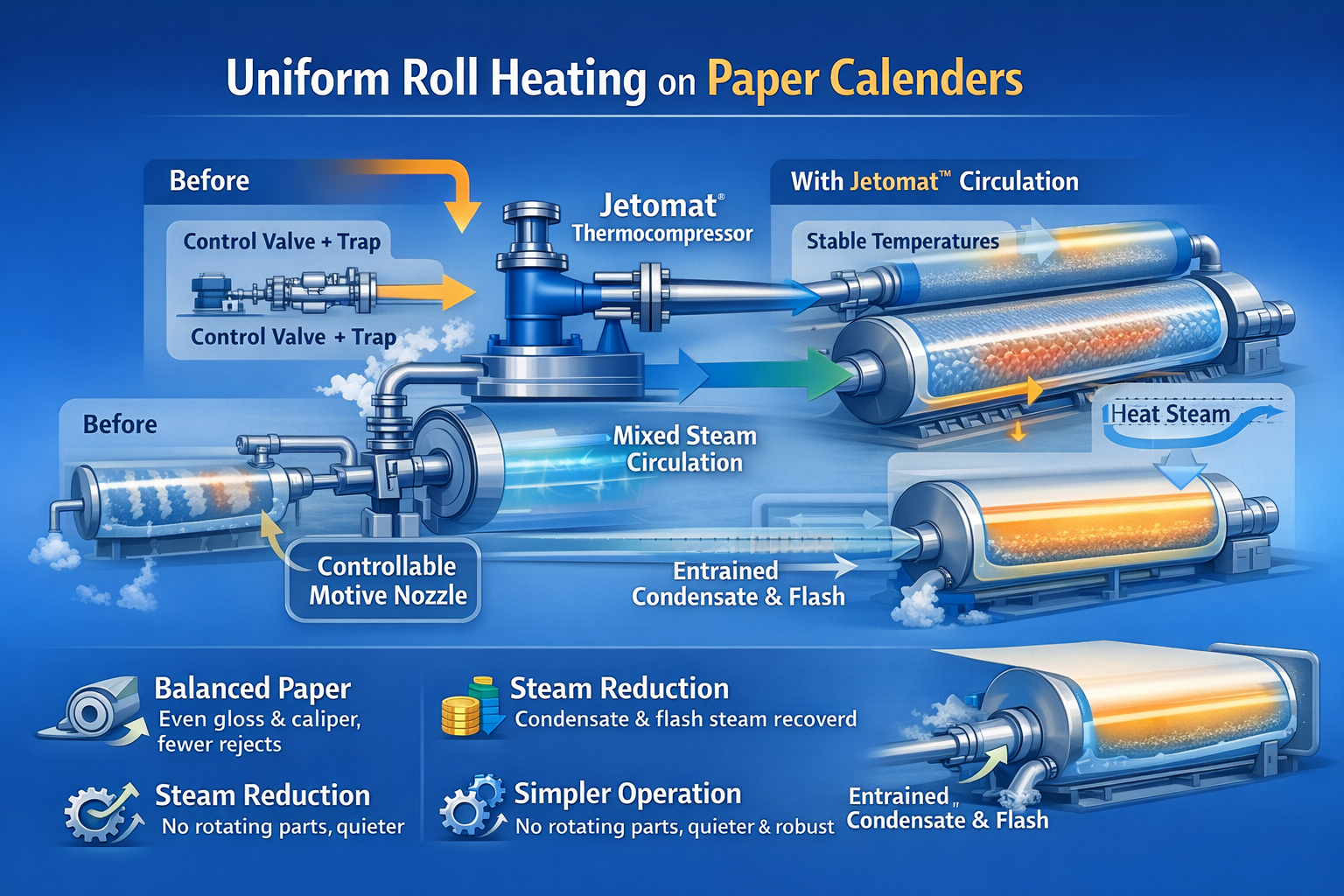

Uniform Roll Heating on Paper Calenders

Jetomat thermocompressors create a circulating steam loop in paper calender rolls, actively pulling condensate/flash steam through the roll so the shell stays uniformly hot during low loads and speed/grade changes.

This reduces gloss bands and caliper variation by stabilizing roll temperature, while also cutting steam losses by reusing flash steam—typically improving quality and saving energy versus valve + trap control.

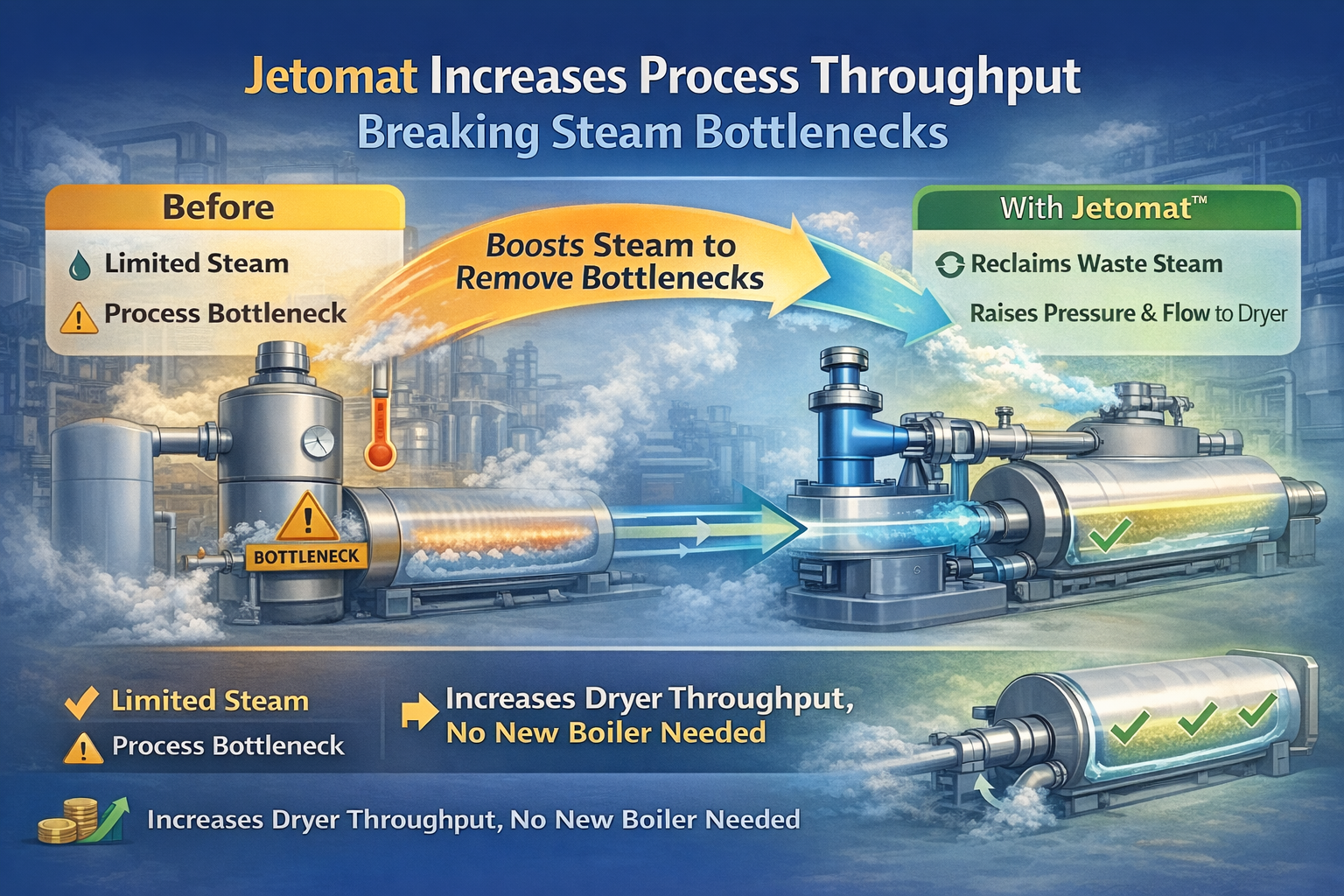

Jetomat Increases Process Throughput Breaking Steam Bottlenecks:

Jetomat thermocompressors help plants break “steam bottlenecks” by boosting usable steam pressure/flow using recovered low-pressure or flash steam—without adding a new boiler or major piping upgrades. This debottlenecks steam-limited equipment (dryers, stoves, spray dryers), enabling higher throughput (often 3–10%+) while reducing live steam demand. The result is more production from the same steam infrastructure, with fast payback and added reliability.

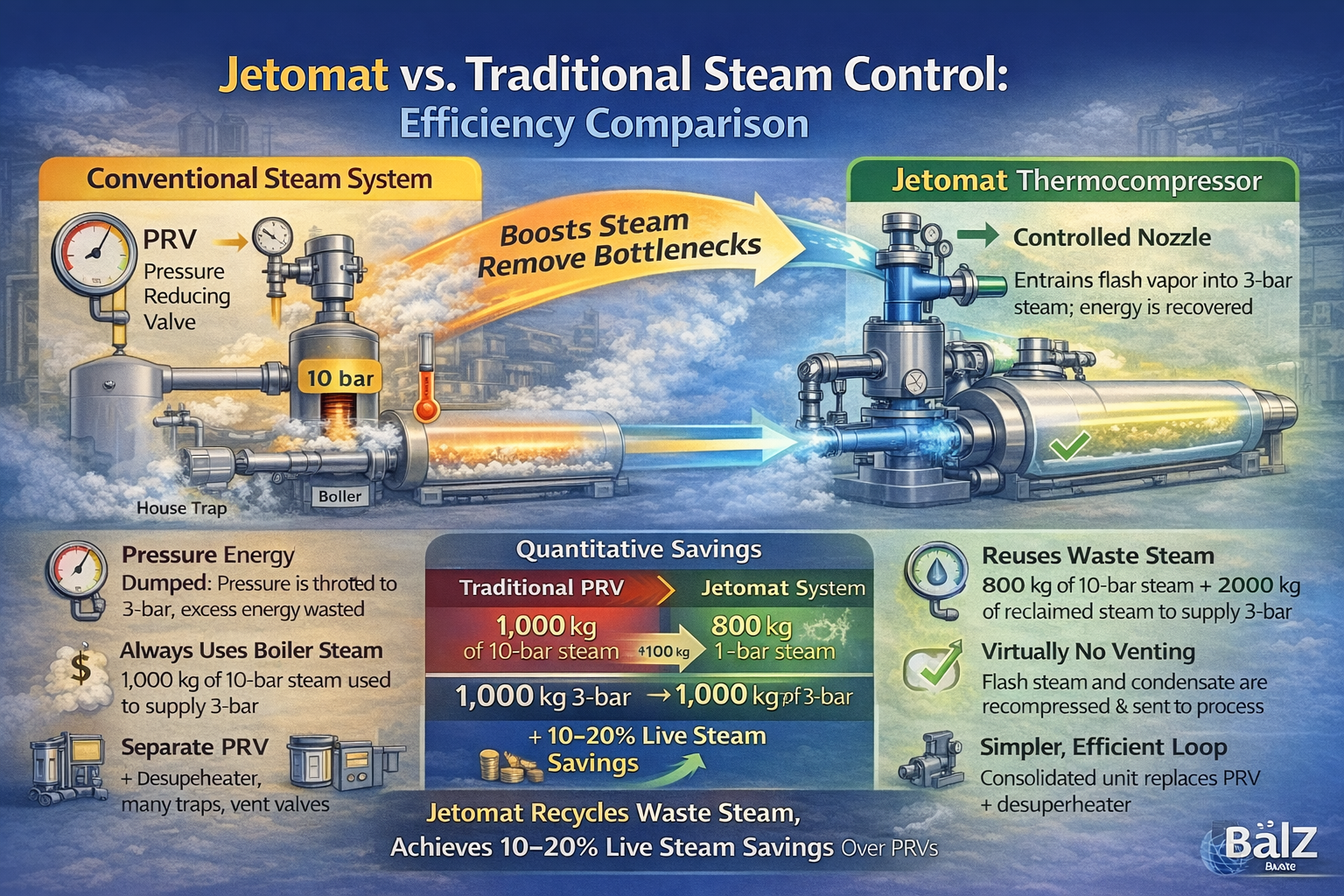

Jetomat vs. Traditional Steam Control: Efficiency Comparison

Traditional steam control uses PRVs to drop pressure and often vents unused/flash steam—so energy is dissipated and fuel is wasted.

Jetomat achieves the same pressure control by using the pressure drop to entrain low-pressure/flash steam, recycling what would be vented.

Result: typically lower live steam demand, less venting, and better overall efficiency.

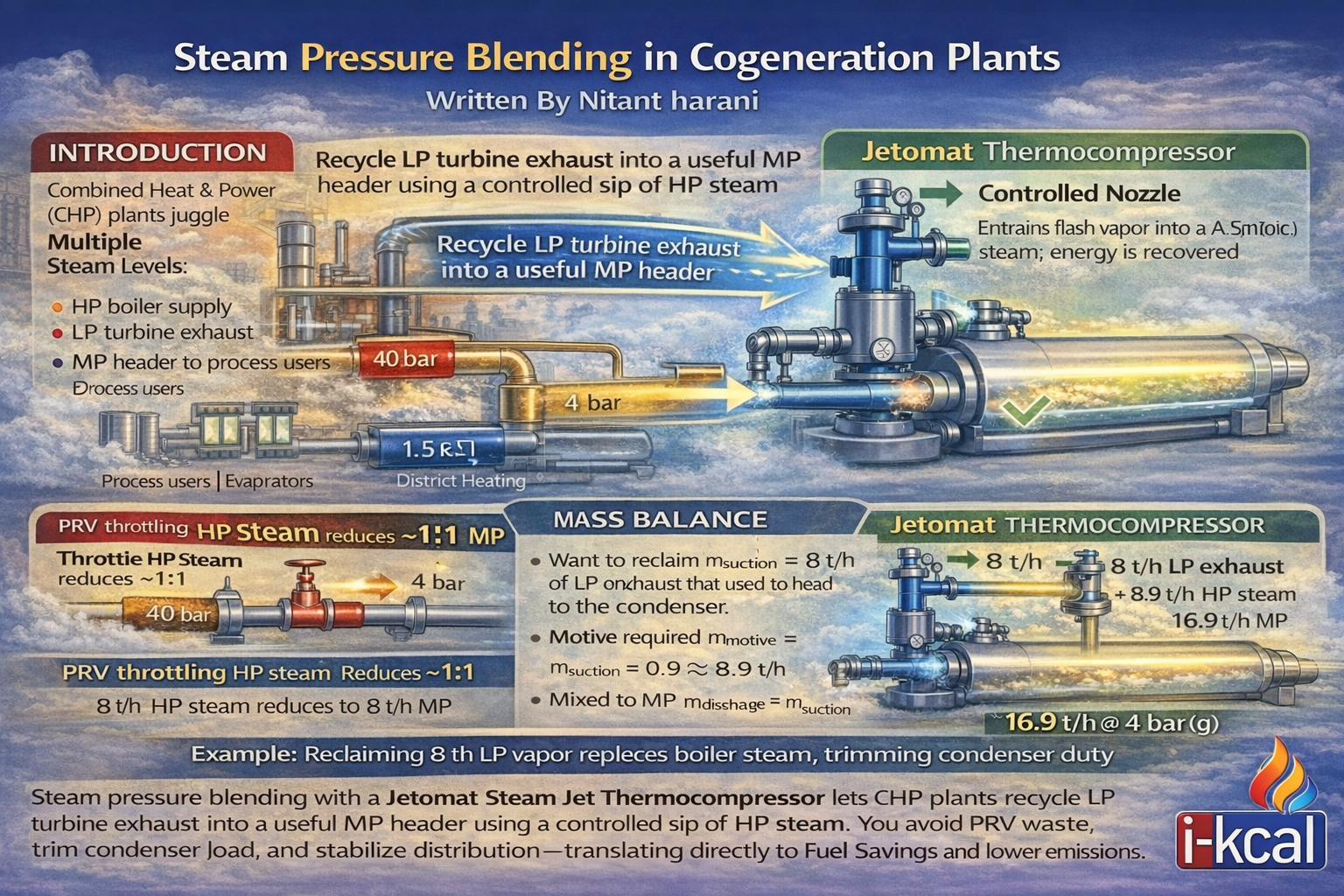

Steam Pressure Blending in Cogeneration Plants

Steam pressure blending in CHP plants uses a Jetomat thermocompressor to mix HP boiler steam with LP turbine exhaust, delivering stable MP steam while recycling vapor that would otherwise go to the condenser.

Compared to PRV throttling, it converts pressure drop into useful work (entrainment), reducing boiler fuel/CO₂, lowering condenser load, and improving MP header stability without adding a new boiler.

Sustainability Wins: How Jetomat Cuts Energy Loss & Emissions

Jetomat thermocompressors help plants meet energy-efficiency and climate targets by recovering waste steam, reducing boiler fuel demand and delivering measurable CO₂ cuts. By minimizing steam venting, they also reduce water loss, treatment chemical consumption, and related boiler-house electricity use—improving both sustainability metrics and operating costs.

No More Steam Traps: Simplifying Steam Systems with Jetomat Technology in Paper Industry

Jetomat steam jet ejectors replace inefficient throttling valves and steam traps in paper dryers, recovering flash steam and improving heat transfer for 15–32% steam savings.

This simplifies the system, eliminates trap maintenance, boosts production speed, and cuts boiler feedwater and chemical use by up to 80% — delivering fast ROI and long-term reliability.

Jetomat transforms steam systems from wasteful and maintenance-heavy to energy-efficient, reliable, and high-performing — with measurable ROI and operational improvements in both paper and textile industries.

Beyond Control Valves: Drum Dryers Save Energy with Steam Jet Ejectors

Traditional steam systems in textile dryers waste energy through throttling and condensate loss; Jetomat steam jet ejectors solve this by recovering and recompressing flash steam.

Jetomat improves energy efficiency (15–30% savings), eliminates the need for traps and valves, and enhances drying consistency and speed.

Real-world textile plant retrofits showed reduced steam consumption, improved temperature uniformity, and increased throughput — all with lower maintenance and simplified systems.