Corrugator Industry Solutions

Increase Production ● 50% Savings ● German Made

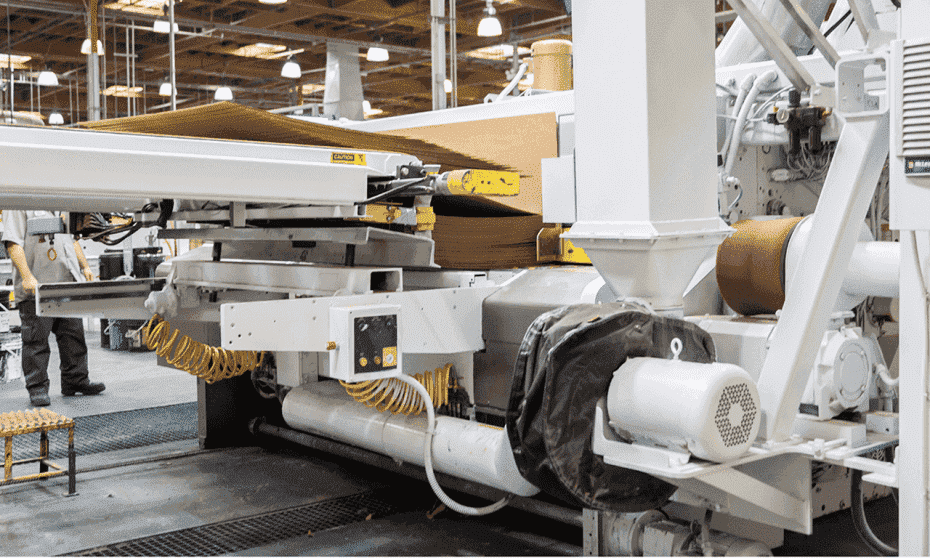

Why Jetomat TurboHeat for Corrugators?

● Faster Heating Cycles for improved productivity

● Significant Energy and Cost Savings through Advance Heating Solution

● Improved Product Consistency ensuring reduced material rejection.

● Reliable Automated Performance with minimal maintenance needs.

● Enhanced Heat Transfer Efficiency for optimal energy utilization

Benefits for Corrugation Industry

Increased Production

Achieve faster drying and bonding processes while minimizing machine speed variations

Significant Energy Savings

Save 25-50% on energy costs through optimized steam control

Enhanced Product Quality

Consistent heating ensures better starch gelatinization, stronger bonding & fewer defects.

Automation & Control

Automated adjustments ensure precise temperature management and consistent performance with minimal manual intervention.

Challenges Faced by Corrugation Industry

Drying & Processing Time

Traditional hearing methods require longer heating cycles and poor temperature control leads to inconsistent bonding and inferior product quality.

Operating Costs

Conventional systems waste energy due to poor heat utilization, requiring excessive boiler pressure(13-16 barg) and increasing operational costs.

Technology Innovation

Many Corrugation plants lack access to reliable heating innovations designed to address these challenges.

Machine Speed Variation

Operators frequently adjust machine speed to maintain quality, reducing production efficiency.

Energy Waste

Condensate and flash steam recovery are vented to the atmosphere, wasting valuable energy.

Maintenance Issues

Frequent clogging of steam traps and pressure fluctuations cause costly downtime.

Consequences of Inefficient Heating

Production Bottlenecks

Slowed machine speed hinder production flow & Machine Throughput.

Reduced Flexibility

Difficulty adjusting temperature profiles for varied board compositions.

Rising Energy Costs

Escalating fuel costs and wasted energy drain profits

Success Story in India

→ 25% Reduction in Fuel Costs

→ Automated Heating Control

→ Consistently Product Quality

Jetomat TurboHeat – Revolutionizing Production

-

Ensure stable heating for improved paper bonding and starch gelatinization

-

Automatically adjust the nozzle size based on load, ensuring optimal energy utilization

-

Provides uniform heating across corrugator hot plates, enhancing bonding strength and reducing temperature fluctuations

-

Efficiently recycles flash steam, adapts seamlessly to fluctuating process demands and optimizes

-

Flexible design options tailor-made for various corrugator companies

Why Choose Jetomat TurboHeat for Your Corrugator Plant?

Jetomat TurboHeat offers a cutting-edge solution that directly addresses the corrugator industry's most critical concerns. With its proven track record, Jetomat TurboHeat delivers:

Improved Drying Efficiency

Shorter drying cycles without compromising product quality.

Superior Product Quality

Ensures consistent texture, softness, and reduced shrinkage.

Energy Saving

Reduces fuel consumption and operational costs.

Maximum Uptime

Reliable performance for uninterrupted production.

Ready to Optimize Your Corrugator Plant?

Our team of experts is ready to analyze your current setup and recommend the perfect Jetomat TurboHeat configuration for your specific needs.