HOT WATER GENERATOR

Reliable. Efficient. German Engineered.

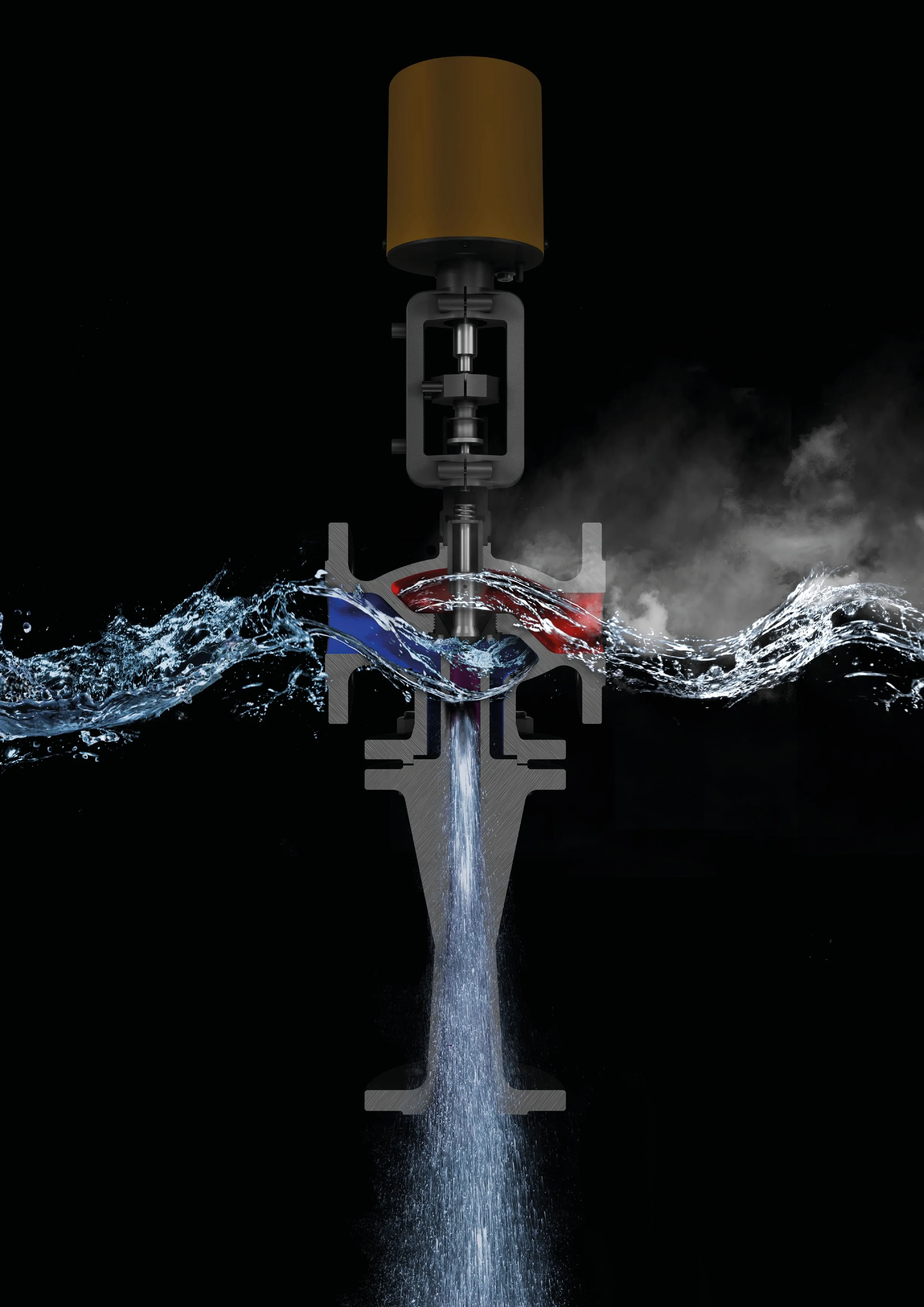

Hot Water Generator Working Principle

Direct Steam Water Mixing

Steam directly injects into water Via Variable Nozzle Ejector, instantly condensing and transferring 100% thermal energy without loss. A Diffuser ensures smooth operation, eliminating vibration and steam hammer.

Indirect Condensate-Control

Steam transfers heat through a flooded heat exchanger. Unique condensate-side control retains steam under vacuum, extracting sensible heat, minimizing steam consumption by 10-15% compared to Conventional PHE Systems.

Benefits of Hot Water Generator

Significant energy and fuel savings

Modern hot water generators are designed to be energy-efficient, minimizing fuel consumption and reducing operational costs.

Lower installation and maintenance costs

Their robust construction and modern design translate to minimal maintenance requirements, leading to years of efficient operation.

Enhanced reliability and equipment lifespan

100% Built in Germany by Baelz, HWG ensure Decades long service life with minimal maintenance requirements.

Consistent, accurate temperature control

Hot water generators are capable of rapidly heating water, minimizing downtime in industrial processes and improving overall productivity.

Key Feature of Hot Water Generator

Direct System

Indirect System

How Hot Water Generator Works?

Direct System

Steam is injected through Variable Nozzle Ejector at Critical High Speed upto 700-900 m/s, under controlled quantity into the incoming water stream. The finely dispersed steam instantly condense upon mixing, transferring all thermal energy directly into the water.

An Actuator dynamically adjusts nozzle size in turn steam flow, ensuring accurate temperature control and eliminating operational issues like steam hammer and Instantly Heating Water from Cold to desired Temperature.

Indirect System

Steam circulates inside a flooded heat exchanger, transferring heat indirectly to the water without direct mixing.

Condensate discharge is precisely regulated to maintain a partial flooding, allowing additional extraction of sensible heat from the condensate.

This controlled method significantly enhances thermal efficiency and reduces steam consumption.

Implementation & Selection Considerations

Choose Direct System for maximum efficiency where steam-water contact is acceptable.

Opt for Indirect System where purity is critical, or flash steam recovery is desired.

Assess steam availability, water quality, and space constraints.

Evaluate based on operational preferences, maintenance ease & future scalability.