Textile Plant Stopped Venting Steam & Started Saving Energy with a Controlled Thermocompressor

65 Kg/Hr Steam Saving

In a continuous textile line, stable heat at the right pressure is everything. At this site, low-pressure steam (2 barg) from process equipment was being vented to atmosphere—an avoidable loss that raised boiler load & energy cost.

The Challenge

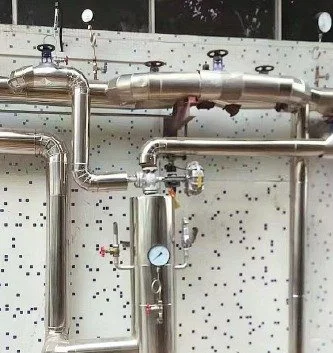

The plant’s heating systems drew medium-pressure steam (3 barg) while a parallel stream of 2 barg exhaust was dumped to the roof. The team needed a compact heat recovery system that would reclaim this flash steam & feed it back into production without disturbing operations.

The Solution

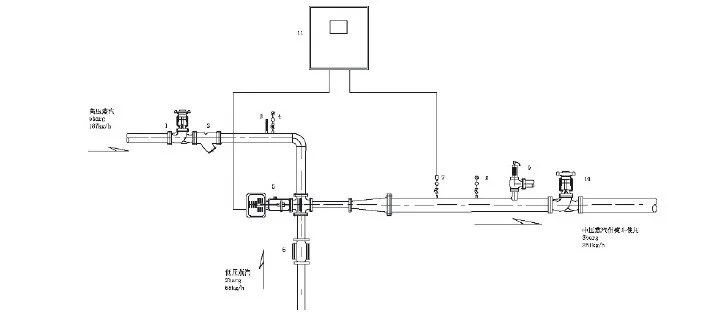

Engineers installed a controlled steam thermocompressor, The unit takes 2 barg suction steam & uses 8 barg motive steam to recompress & regulate the mixture to 3 barg, directly supplying consumers. Practically, every kilogram of 2 barg steam recovered displaces 1 kg of new 3 barg steam, cutting make-up demand at the boiler. The result: no more direct exhaust steam from the plant.

The Results

Direct Venting Eliminated: 65 Kg/Hr exhaust steam — converted to productive energy.

Fuel displacement: each 1 kg of recovered 2 barg steam reduces 3 barg demand by 1 kg, easing boiler load & chemicals/water use.

Simple integration: the controlled thermorecompressor continuously regulates to 3 barg, matching consumer needs without re-piping major sections.

Operational Benefits

Tighter temperature control across dryers, washers, & finishers via stable 3 barg supply from recovered vapor.

Lower OPEX from reduced boiler make-up—an immediate heat transfer solution that complements steam separator placement & condensate & flash steam recovery system practices.

Robust & low-maintenance: ejectors have no rotating elements, making them ideal retrofits for variable loads common in textile processing.

Why This Works

A Steam Jet Ejector uses high-pressure motive steam expands through a Variable Nozzle Area, entrains low-pressure vapor, then the mixture recompresses in the diffuser & nozzle section to the desired setpoint—operating like a steam compressor but with no moving parts.

With proper thermocompressor design & control, it delivers stable pressure/flow to downstream steam equipment while saving energy by turning waste steam & condensate losses into useful heat.

Takeaway

If your textile plant vents low-pressure steam, a steam jet thermocompressor is a proven route to saving energy:

Reclaim low pressure exhaust, blend with motive & feed reliable recycled steam back to users — with no moving parts & minimal footprint.

Pair it with good steam & condensate housekeeping to maximize gains.

Project Details

Location: Guangdong Province, China

Technology: Controlled Thermocompressor Jetomat

Industry: Textile

Company: Printing and Dyeing Factory