15% Steam Saving in Textile Washing & Drying

↑↑↑

Production Speed

15%

Steam Saved

0

Steam Traps

The implementation of Baelz 590 steam thermocompressor in place of traditional control valves as per end Customer has resulted in approximately 15% steam savings, elimination of steam traps, improved heat distribution & better drying quality.

The Jetomat® Turboheat® technology has proven to be an effective solution for enhancing energy efficiency and process performance.

Case Study Overview

A textile washing and drying factory in Turkey implemented Baelz controlled steam ejectors (Jetomat®) to replace traditional control valves, resulting in significant energy savings and process improvements.

The Retrofit led to approximately 15% steam savings, elimination of steam traps, improved heat distribution & better drying quality.

Original Situation

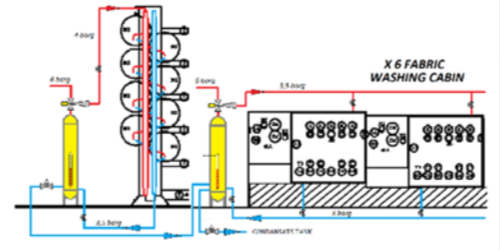

1 Row Drying Stage with 5 Drum Dryers & 6 Washing Baths were Control Valve with Individual Steam Traps were used.

Technical Enhancement

The control valves were replaced with baelz 590 steam ejectors, resulting in improved parameters for both processes.

Drying Process

1-row drying stage with 5 drum dryers

Controlled by a control valve

5 steam traps, One on each drum

BEFORE

Live Steam = 6 barg

To Dryer = 4.5 barg

Steam Flow = 200 - 500 kg/h

AFTER

Live Steam = 6 barg

To Dryer = 4 barg

Steam Flow = 15% Lower

Washing Process

6 washing baths

Steam trap used in each bath

BEFORE

Live Steam = 6 barg

To Washing = 4 barg

Steam Flow = 800 - 1000 kg/h

AFTER

Live Steam = 6 barg

To Washing = 3.5 barg

Steam Flow = 15% Lower

Benefits of Jetomat Turboheat

Project Details

Location: Turkey

Baelz Technology: Controlled steam ejectors Jetomat®

Industry: Textile

Company: Washing and drying factory