Textile Line Cut Steam Use 20%

Switching to Controlled Thermocompressors

20%

Steam Saved

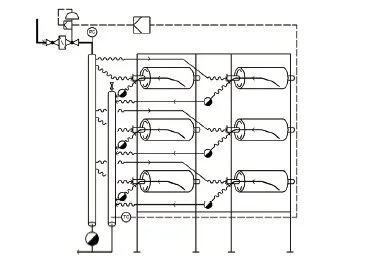

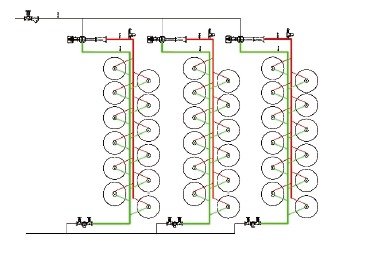

A continuous textile line with a 3-row dryer stage (each row 12 drum dryers) was originally valve-controlled, driving up steam demand & limiting speed/quality. A retrofit replaced control valves with baelz 590 controlled steam thermocompressor to stabilize drying & save energy.

The Challenge

With valve control, internal steam condensate films stayed thick inside the drums, slowing heat transfer & capping production speed.

Baseline parameters on the section were

Motive = 5.5 barg

Discharge = 3 barg

Steam Load = 200–600 kg/h

depending on textile material—conditions that left efficiency on the table.

The Solution

The plant replaced the control valves with steam thermocompressor.

After retrofit, operating points settled at

Motive = 5.5 barg

Suction = 1.5 barg

Discharge = 2 barg. (1 Barg Lowered)

Steam Load = 20% Lower (As per end customer)

The Results

20% steam saved (As per End Customer)

“Monthly steam consumption” improved from 2.6 t → 2.2 t (as reported in the case).

Higher production speed & better drying quality from thinner condensate films & steadier pressure.

Why This Works

A controlled steam jet thermocompressor acts as a steam compressor without moving parts.

Correct thermocompressor design & nozzle design lift internal velocities, minimize film thickness, & stabilize setpoints

—delivering heat transfer solutions that reduce steam per meter processed while enhancing line runnability.

When paired with good steam & condensate practice (e.g., steam separator, flash steam routing, condensate & flash steam recovery system), savings compound across the section.

Takeaway

If your dryers are valve-controlled & you’re fighting venting or high steam per kg of fabric, a controlled steam thermo compressor can be a fast, low-maintenance route to saving energy:

recover with steam jet ejectors, improve drying, & unlock speed—without adding rotating machinery.

Project Details

Location: Hebei Province, China

Technology: baelz 590 controlled steam ejectors

Industry: Textile

Company: Printing and Dyeing Factory