Sappi Fine Paper Boosted Stove Throughput with

A Controlled Steam Jet Thermocompressor

3-5% Production Increase

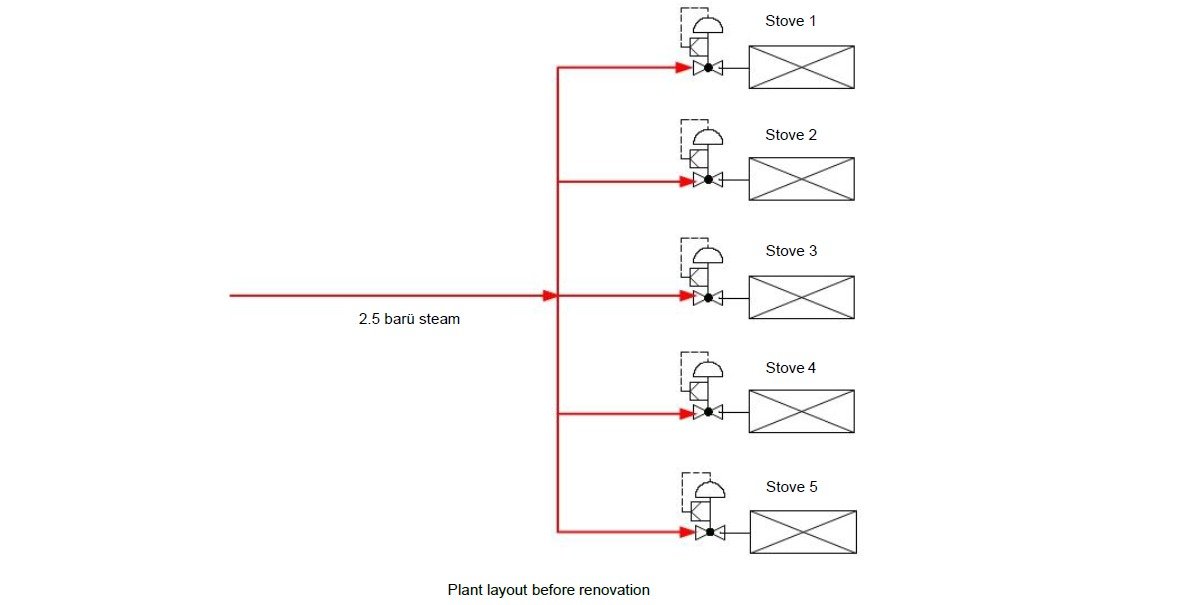

At Sappi Fine Paper’s Gratkorn site near Graz, wood chips are charged into several parallel stoves using steam “impulse” pressure. Before optimization, the stoves were supplied with about 2.5 bar steam, which limited filling efficiency.

The Challenge

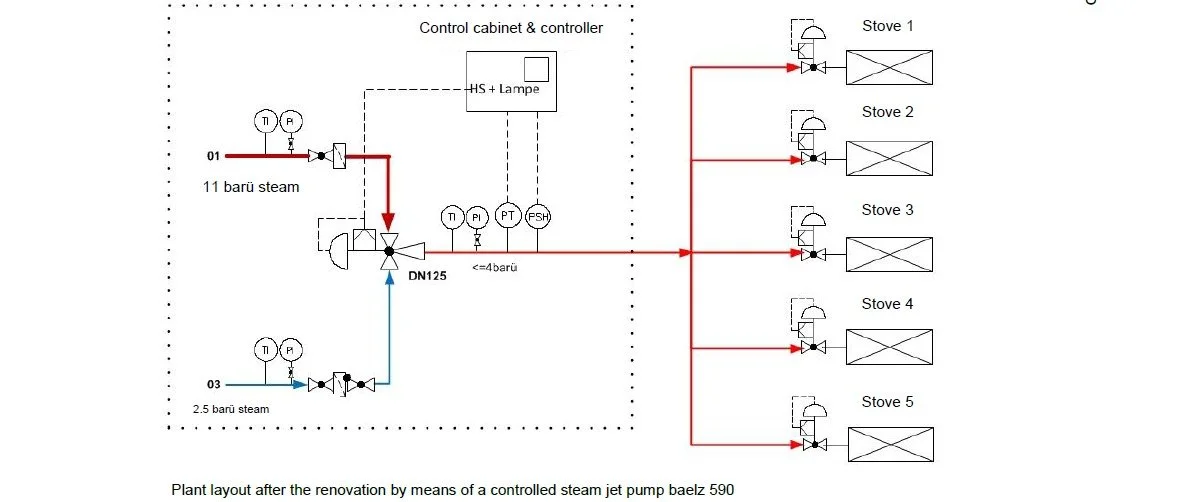

Increasing the degree of filling in each stove required higher inlet steam pressure—without reworking the entire steam system. The goal was to lift the pressure up to ~5 bar while keeping the multi-stove arrangement & existing controls intact.

The Solution

Sappi installed a controlled steam jet pump (Baelz 590, DN125, PN16) as a steam compressor/thermocompressor. The ejector blends the existing 2.5 bar steam with an 11 bar motive steam rail to deliver roughly 4 bar at the stove inlet, with the option to regulate higher when needed via stroke control. Quantity control per stove remained by the existing control valves, & only one stove is filled at a time, preserving the operating concept.

The Results

Throughput: Each filling process increased by ~3–5%, raising overall process efficiency.

Economics: The project paid for itself within a few months, thanks to the improved filling performance & reduced throttling losses—clear saving energy impact.

Why This Works

The upgrade applies the steam jet ejector working principle: high-pressure motive steam expands through the nozzle (nozzle design), creating a suction that entrains the lower-pressure stream; the mixture then recompresses in the mixing tube & diffuser to the target pressure. In effect, the vapor compressor / steam jet compressor converts available motive pressure into usable process pressure, improving stove charging without adding moving parts to the steam equipment.

Takeaway

Where chip/stove charging or dryer sections struggle with limited pressure, a steam thermocompressor / steam jet thermocompressor (e.g., Baelz 590) can deliver higher, controllable inlet pressure & stabilize operation—with modest footprint & short payback. Plants evaluating heat transfer solutions should also review steam & condensate handling (e.g., steam separator, flash steam routing, condensate & flash steam recovery system / heat recovery system) to compound benefits.

Project Details

Location: Gratkorn, Austria.

Technology: Controlled Steam Thermocompressor retrofit (Baelz 590 DN125 PN16)

Industry: Paper

Company: Sappi Fine Papers