Disc Dryer Saves 30 LPA in Steam

With 18% Performance Boost Jetomat TurboHeat

+1 Additional Batch

+18% Performance Increase

195 Kg/Hr Steam Saving

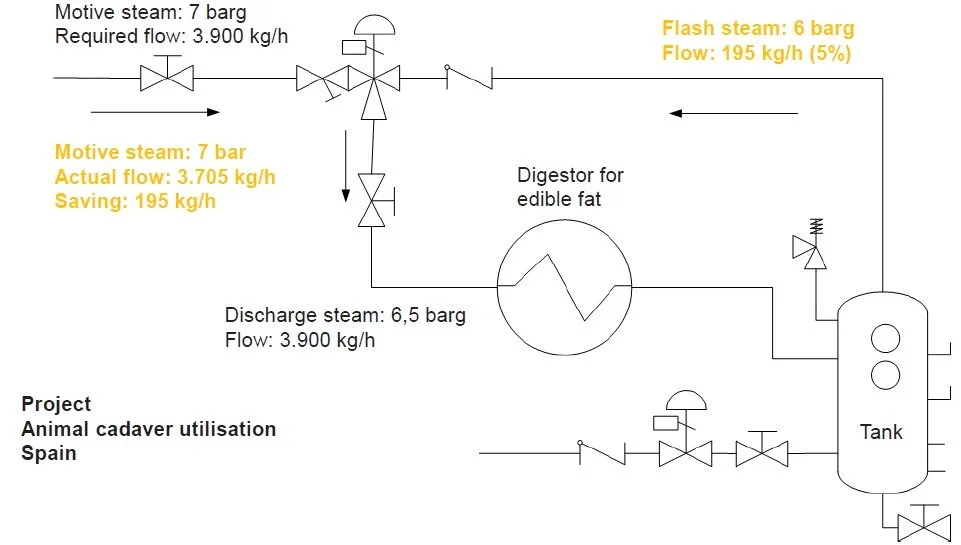

Recirculation-590 (Jetomat Turboheat) applied to a disc dryer with steam and condensate recirculation. The circuit uses a Jetomat steam thermocompressor to pull flash steam from a condensate tank and return mixed (discharge) steam to the dryer, ensuring continuous flow and heat distribution.

The Challenge

Intermittent condensate removal and pooling in the Cylindrical disc dryer led to uneven heating.

Flash steam from the condensate tank was vented, wasting energy.

Throttling through valves caused pressure loss without recovery, while numerous steam traps increased maintenance.

The Solution

Deploy Jetomat 590 in recirculation mode:

The steam jet ejector uses high-pressure motive steam through a Variable Area nozzle to create suction and entrain flash steam from the condensate tank.

In the diffuser, velocity is converted back to pressure; the combined stream returns as discharge steam to the dryer, keeping steam and condensate circulating & Active Suction for Condensate Removal resulting in thinner Condensate Layer In Dryer.

The loop maintains the provided operating window: motive 7 barg, flash 6 barg (195 kg/h, 5%), discharge 6,5 barg at 3.900 kg/h, with actual motive flow 3.705 kg/h (saving 195 kg/h).

The Results

Performance Benefit:

5% Decrease in Steam consumption

18% Increase of Dryer Throughput

+1 Batch/day (Additional Batch)

Savings Benefit:

195 kg/h of Steam Saving

29.250€ (30.71 Lacs) annual saving *

25.000€ (26.25 Lacs) capital investment

Payback Period < 1 year

* 25 €/t (2,625 Rs./Ton) cost of steam

* 250Days/Yr

Why This Works

Condensate Drained with Active Suction

➔ less condensate, better heat distribution

Higher steam Flow

➔ Equal heat transfer, no local overheating

Thiner condensate layer

➔ higher temperature, reduced temperature difference

Increased Production Output

➔ Higher Heat Transfer Coefficient

Takeaway

Jetomat Thermocompressor turns an open, trap-heavy dryer loop into a Closed, Circulating heat-recovery system.

With the exact figures above—

3,705 kg/h Motive Flow at 7 barg motive,

195 kg/h Flash Steam at 6 barg

6.5 barg discharge at 3,900 kg/h

the site achieved :5% steam savings, 18% performance gain, +1 cycle/day & payback < 1 year.

Project Details

Location: Spain

Technology: Baelz-vapordynamic® controlled steam ejector.

Industry: Meat Processing

Company: Meat Processing Company