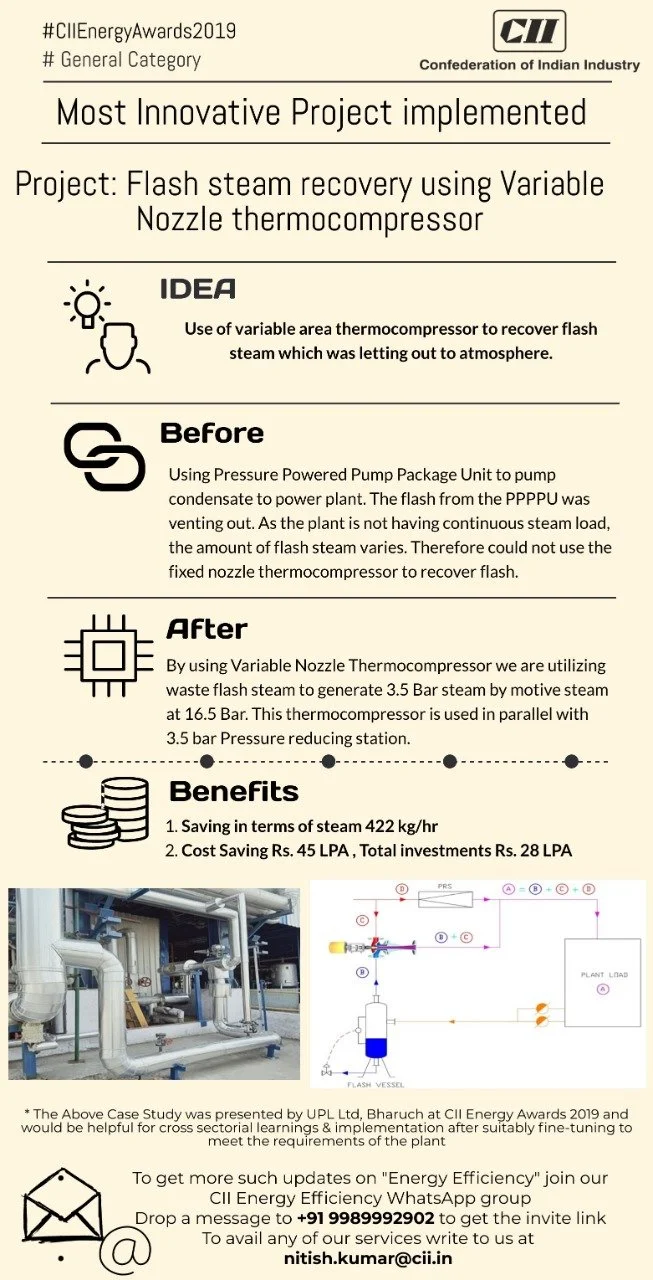

Flash Steam to Productive Steam: How a Chemical Plant in Bharuch Turned Losses into Savings

422 kg/h

Steam Saved

45 LPA

Monetary Benefit

The Challenge

The plant pumped steam condensate to the power plant via a pressure-powered pump package unit (PPPPU).

The resulting flash steam was venting to atmosphere. Because steam load varied across the heating systems, a fixed-nozzle thermocompressor couldn’t recover this energy reliably.

The Idea

Adopt a variable nozzle thermocompressor to flex with changing flash volumes, entrain waste vapor, & convert it into usable low-pressure steam—without disturbing production.

The Solution

A Variable Nozzle Thermocompressor was engineered into the plant’s steam equipment & tied in parallel with the 3.5 bar pressure-reducing station.

Using motive steam at 16.5 bar, the unit entrains vented flash steam, mixes it in the diffuser & nozzle section, & recompresses it to deliver 3.5 bar steam back to the process—creating a compact flash steam recovery system & heat recovery system in one.

The Results

Steam saved: 422 kg/h

Cost saving: ₹45 lakh per Annum

Investment: ₹28 Lakhs

Operation: Runs alongside PRS; stable supply at 3.5 bar; no change to production routing

Why This Works

This approach leverages the variable jet ejector working principle: high-pressure motive steam accelerates through a nozzle, entrains flash steam, & the mixture recompresses in a diffuser.

Because the thermo compressor uses a variable nozzle, it adapts to fluctuating flash volumes, ensuring consistent recovery & pressure—ideal for chemical-plant duty where process loads shift.

Takeaway

If your steam separator & condensate lines routinely vent flash steam, a variable-nozzle thermocompressor offers a practical path to saving energy—especially where loads vary & fixed jets struggle.

Evaluate a condensate & flash steam recovery system built on steam jet compressors to turn atmospheric losses into usable process steam with proven ROI.

Operational Benefits

Cuts vent losses; transforms waste steam & condensate handling into recovered energy

Reduces PRS throttling by supplying part of the 3.5 bar demand from recovered flash

Compact, low-maintenance heat transfer solution with no moving parts in the jet body

Improves utility KPIs & supports sustainability targets