German Textile Plant Cut Primary Energy by

15% with a New Steam & Power Concept

15%

Energy Saved

12%

CO₂ Reduction

A leading textile & finishing company in Germany overhauled its utility plant to stabilize production, generate its own electricity, & Save Energy. The project replaced aging oil-fired Steam Equipment with a high-efficiency combined heat & power (CHP) solution & modern steam stations.

The Challenge

The site ran Three Heating-Oil Steam Boilers, supplying some steam directly to process while routing the Largest Share to a gas turbine for power. At Partial Load, the turbine’s efficiency fell sharply—driving up primary energy use & carbon emissions, & risking seasonal stoppages.

The Solution

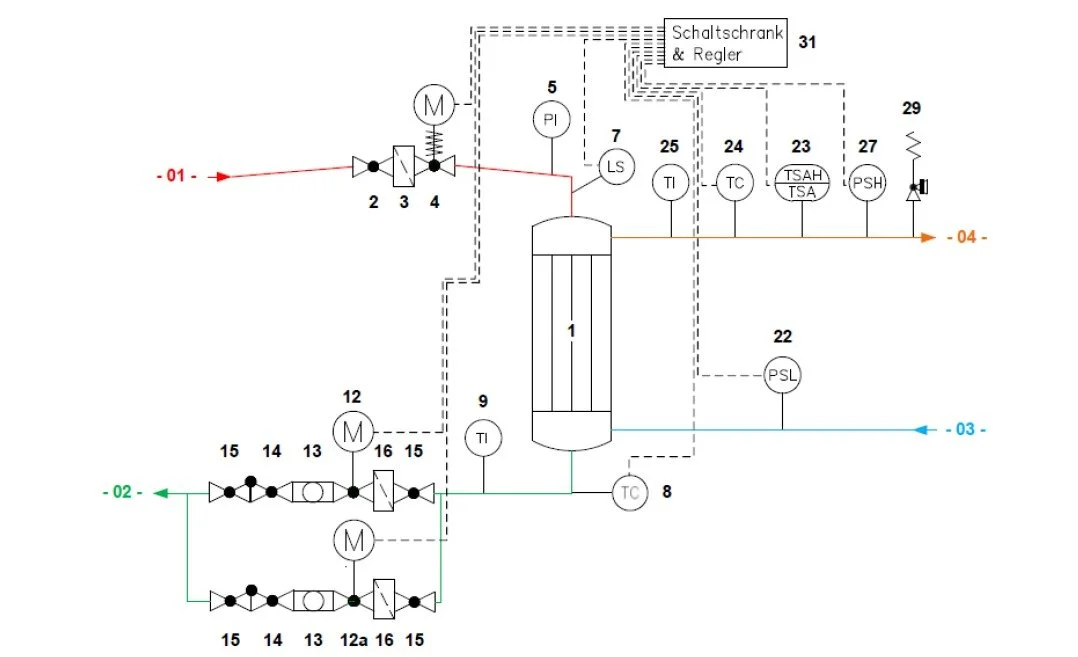

The plant Reoriented its Energy Concept: the old boilers were replaced with a Gas-Fueled Power Plant (CHP) that produces Steam, Hot Water, & Electricity; electrical output is just under 2 MW & flexes with demand. A new Gas-Operated Steam Boiler now secures process steam during CHP maintenance or outages. Steam is generated at 25 bar & reduced to 5.5 bar for manufacturing by a Baelz Steam Pressure-Reduction Station. A Baelz Steam-Forming Station also converts 5.5 bar steam into 110 °C Pumped Hot Water—a compact Heat Recovery System for the plant’s Heating Systems. Products supplied included a Steam Transfer Station, Pressure-Reduction Station, & a Steam Distributor with Fittings.

The Results

15% Primary Energy Reduction & 12% CO₂ Reduction (operator-confirmed).

Self-Generation of Electricity covers almost all site demand via CHP.

Operational Resilience: “a complete operating standstill is no longer necessary in the summer,” with processes run More Optimally & Variably.

Why This Works

Pairing CHP with correct Steam & Condensate conditioning improves overall plant efficiency:

High-efficiency power generation plus useful heat (steam/hot water) to the process, & Precise Pressure Staging (25 → 5.5 bar) to match equipment needs.

The Steam-Forming Station (Desuperheater) adds flexible hot-water capacity at 110 °C without separate boilers—simplifying utilities & reducing losses.

Takeaway

If your utilities rely on aging boilers or inefficient partial-load operation, a CHP-Centered redesign with modern Steam Stations can deliver rapid gains:

lower primary energy, lower CO₂, & steadier production. As you plan upgrades, evaluate complementary Heat Transfer Solutions (e.g., pressure/temperature staging, Steam Separator placement, & Flash Steam routing) to maximize outcomes.

Project Details

Location: Germany

Technology: Steam Transfer Station, Steam Pressure Reduction Station, Steam Distributor with Fittings

Industry: Textile

Company: Textile Finishing Company