Stop Throttling, Start Recycling: Steam Ejectors vs. Pressure-Reducing Valves

Short version: Pressure-reducing valves (PRVs) drop pressure & throw exergy away. Steam jet ejectors recycle that energy by entraining flash steam & returning it to the process.

Result: saving energy (often double-digit %), fewer moving parts, & steadier heating systems

The core problem with throttling (PRVs)

A PRV’s job is to reduce pressure. That’s it. When you throttle 12–15 bar steam down to, say, 3–6 bar, the lost pressure potential isn’t recovered—while downstream steam condensate & flash are typically dumped via traps/vents. In dryer lines & heat users, that shows up as:

Thicker condensate films → lower heat transfer

Unstable temperatures → quality variability

Venting of flash steam → visible, billable energy loss

Real plants that swapped valves for ejectors reported ~15% lower steam per ton on a paper machine (from 2.6 t/ton to 2.2 t/ton), simply by replacing throttling with recovery.

What a steam thermocompressor actually does

Think of Jetomat as a steam compressor. Using a carefully engineered Variable nozzle design & diffuser & nozzle geometry, it accelerates a small flow of motive steam to create suction that pulls in low-pressure vapor (flash steam). The diffuser then converts velocity back into pressure, delivering a mixed steam stream at your setpoint.

That’s the steam jet ejector working principle

· PRV path: high-pressure steam → throttled to low pressure (energy lost)

Ejector path: high-pressure motive + low-pressure suction/flash → recompressed mixed steam (energy recovered)

Across industries, compression-mode ejectors commonly deliver 10–30% direct steam savings as a flash steam recovery system / heat recovery system.

Why recycling beats throttling

You don’t need to change the boiler. You change how you feed & manage the user:

Paper machine dryer: swapping valves for ejectors reduced specific steam from 2.6 → 2.2 t per ton (≈15% saving) & improved drying stability.

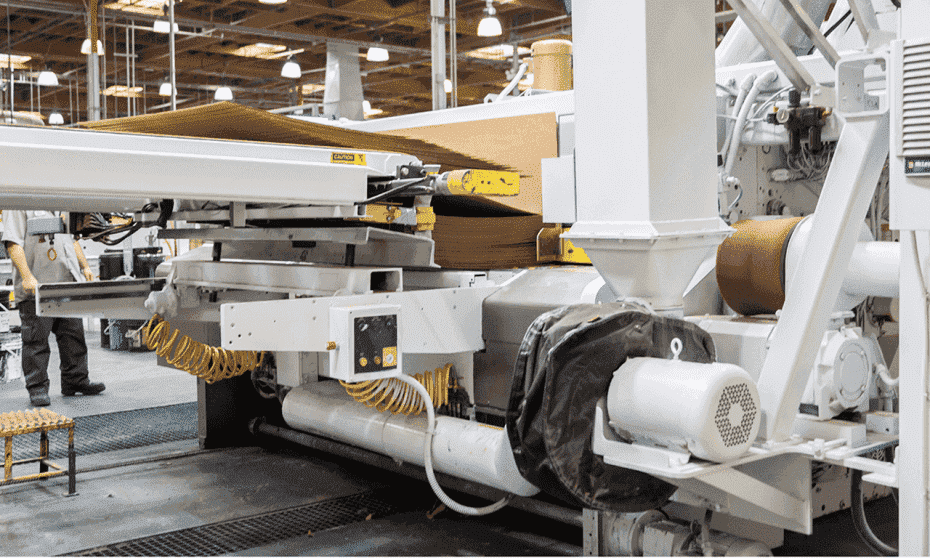

Corrugated/paper dryer groups: retrofit with steam jet ejectors saved ≈32% steam & cut boiler feedwater & chemicals ~80% (keeping steam & condensate in the loop). It also removed the need for traps on that section.

Textile dryers: 1-row stage (~5 drums) reported ≈15% steam savings & eliminated drum-level traps; a 3-row (36 drums) line reported ≈20% steam reduction.

Food & beverage evaporator service: right-sized ejector replacement delivered ~₹ 187 Lacs / Year savings with a 1.68-month payback—same physics as in other process lines.

Heat transfer wins you can feel

When ejectors entrain vapors, cylinder/heat-exchanger steam velocity rises & the condensate film thins. That improves heat transfer solutions:

Higher effective surface temperature for the same supply pressure

Flatter temperature profile across rolls/surfaces → better quality

Often, a noticeable boost in line speed/throughput

These effects were observed repeatedly in paper & textile dryers after switching to ejectors.

Fewer components, fewer headaches

A PRV + trap network often needs a steam separator, flash tank, vents & many traps. With a steam jet thermocompressor, much of that is simplified because you re-use the flash—forming a built-in condensate & flash steam recovery system. Results in the field include removing multiple traps (sometimes all) on a dryer group & operating with steadier temperatures.

Design notes that matter (& pay back fast)

Sizing matters: An oversized unit can force venting; a recalculation downsized one application from DN150 to DN100 & fixed chronic blow-off—unleashing the savings.

Control point: You can hold mixed-steam pressure (p₄), temperature, or other proxies—ejectors play nicely with modern controls/PLCs used across steam equipment.

ROI reality: With 10–30% savings common, payback windows measured in months are not unusual—especially where vent losses are visible.

Quick comparison — PRV vs. Steam Ejector (Jetomat)

Feature / Outcome PRV (throttle)

Energy healing Drops pressure → energy lost

Heat transfer Lower velocities, thicker films

Stability Sensitive to load shifts

Hardware PRV + many traps + vents/flash

tank/steam separator

Maintenance Traps/valves to survey & fix

Typical results Status quo

Steam ejector (Jetomat)

Recycles flash + motive → usable mixed steam

Higher velocity, thinner films, better transfer

Stable mixed-pressure control

Thermo compressor + simplified loop

Ejector has no moving parts in the flow path

15–32% steam savings, fewer traps, higher throughput

Where this helps

Anywhere you have a pressure step & vapor generation: evaporators, reboilers, cookers, sterilizers, concentrators—across food & beverage, chemicals, paper, textiles, & more. If you see vent plumes, frequent trap issues, or big PRV drops, a thermo compressor working principle is a fit.

FAQ — common engineering questions

Q1. Do I still need a flash tank or separator?

A. Many systems can simplify or eliminate dedicated flash h&ling because the ejector acts as a vapor compressor that re-uses flash. Your exact layout depends on code & duty, but simplification is a frequent outcome.

Q2. Will it integrate with my current controls?

A. Yes. Ejectors regulate via motive steam control & standard instruments. Several case studies replaced only the throttling element with Jetomat while keeping existing DCS/PLC logic.

Q3. What savings should I assume?

A. Start with a conservative 10–20% for throttled users; sites with visible venting or heavy trap maintenance often had higher (up to ~30%+). Validate with a short site survey & mass/energy balance.

Implementation roadmap

Walk-through & data: Pressures/flows, vent points, trap count, control logic.

Thermocompressor design: Size Jetomat to your loads & pressure targets. (Right-sizing is critical to capture savings.)

Pilot user: Convert one throttled user (dryer group, evaporator, etc.) → measure.

Scale-out: Roll to other throttled services once the numbers confirm.

Takeaway

Stop throttling. Start recycling. Swapping PRVs for Jetomat steam ejectors turns a pressure drop into a heat recovery system. Plants have documented 15–32% steam savings, big reductions in make-up water/chemicals, & simpler loops with fewer traps—often with payback in months, not years.

Get a Free Evaluation

Curious what a steam jet thermocompressor could save on your line? Request a free evaluation. We’ll review your steam & condensate data, identify flash steam recovery system opportunities, & propose a right-sized Jetomat to start saving energy—with a clear, numbers-first justification.