Wood Processor in Austria Expanded Drying Capacity Without Rebuilding the Network

60 LPA

Monetary Saving

36 Months

Payback

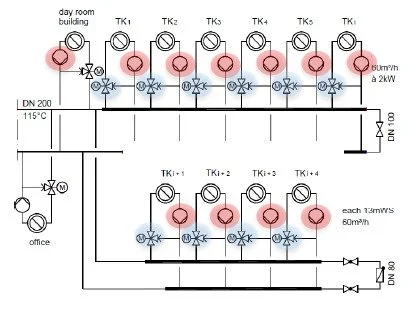

A wood processing plant in Kundl, Austria needed to add 4 New Drying Ovens to the existing 13 (total 17). The site’s District Heating Grid could not support the extra load as built. Rather than enlarging the grid or laying a parallel network—both high-capex options—the plant converted to Baelz Jetomat® Water Jet Pump Technology.

The Challenge

Raising drying capacity typically means bigger pipework, more circulation pumps, & additional mixing valves. Here, both options considered—increasing the existing network or building a parallel network—would have required significant investment & complexity, with no guarantee of lower operating costs.

The Solution

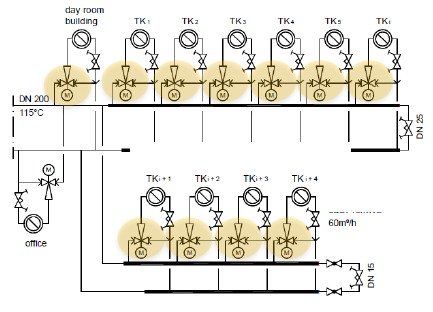

The utility team re-engineered the network to use Jetomat® 480 Water Jet Pumps in place of Circulation Pumps & Mixing Valves. The revised concept keeps a Single Main Pump & employs Water Jet Pumps to drive mixing & distribution across the 17 ovens, avoiding a costly district-heating rebuild while improving hydraulic performance & control.

Key project data

Annual Operating Time: 8,760 hours

Thermal Output: 8,000 kW (8 MW)

Main Pump Capacity: 18.0 kW (post-conversion)

Circulation Pumps Removed: 59.0 kW (total previously installed)

Electricity Price (assumption): €0.11/kWh

Total investment: €200,577

The Results

Operating Cost (before):

77.91 Lacs/Yr (€74,200/year)

(8,760 h × (18 kW + 59 kW) × €0.11/kWh)Operating Cost (after): ≈

18.27 Lacs/Yr (€17,400/year)

(8,760 h × 18 kW × €0.11/kWh)Annual Saving: 60 Lacs (€56,800)

Payback: 3 years

Beyond the arithmetic, the plant Optimized Heat Distribution in the drying ovens & avoided the entire grid expansion, cutting both capex & opex while unlocking the desired capacity increase.

Why This Works

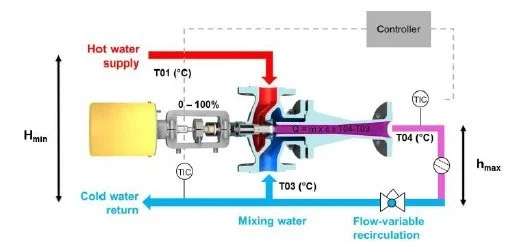

Jet Pump Technology leverages the Bernoulli Principle:

A Reduced Cross-Section inside the jet pump accelerates the flow & lowers pressure, which Aspirates Return Water & mixes it—so a traditional mixing valve & multiple circulation pumps are no longer required.

This simplifies hydraulics & improves controllability under varying loads.

Additional Advantages Reported:

No Circulation Pumps needed; only one main pump

Stable Regulation & Optimized Heat Distribution

Lower Electricity & Cabling Costs; Fewer Fittings & Data Points for the BMS

Lower Maintenance, Higher Operational Safety, & Shorter Amortization

Takeaway

If your drying capacity is capped by the Existing Heater, consider a Jetomat® Water Jet Pump conversion.

This case shows how 17 ovens can be supplied without a new Heater, delivering 60Lacs/year in electricity savings & a 3-year Payback, while improving distribution & control across the dryers.

Project Details

Location: Austria

Technology: Jetomat® 480 Water Jet Pumps

Industry: Timber/Wood Drying

Company: Wood processing plant, Kundl