Stop Venting Steam: A Textile Mill Recycles Waste Steam with Thermocompressors

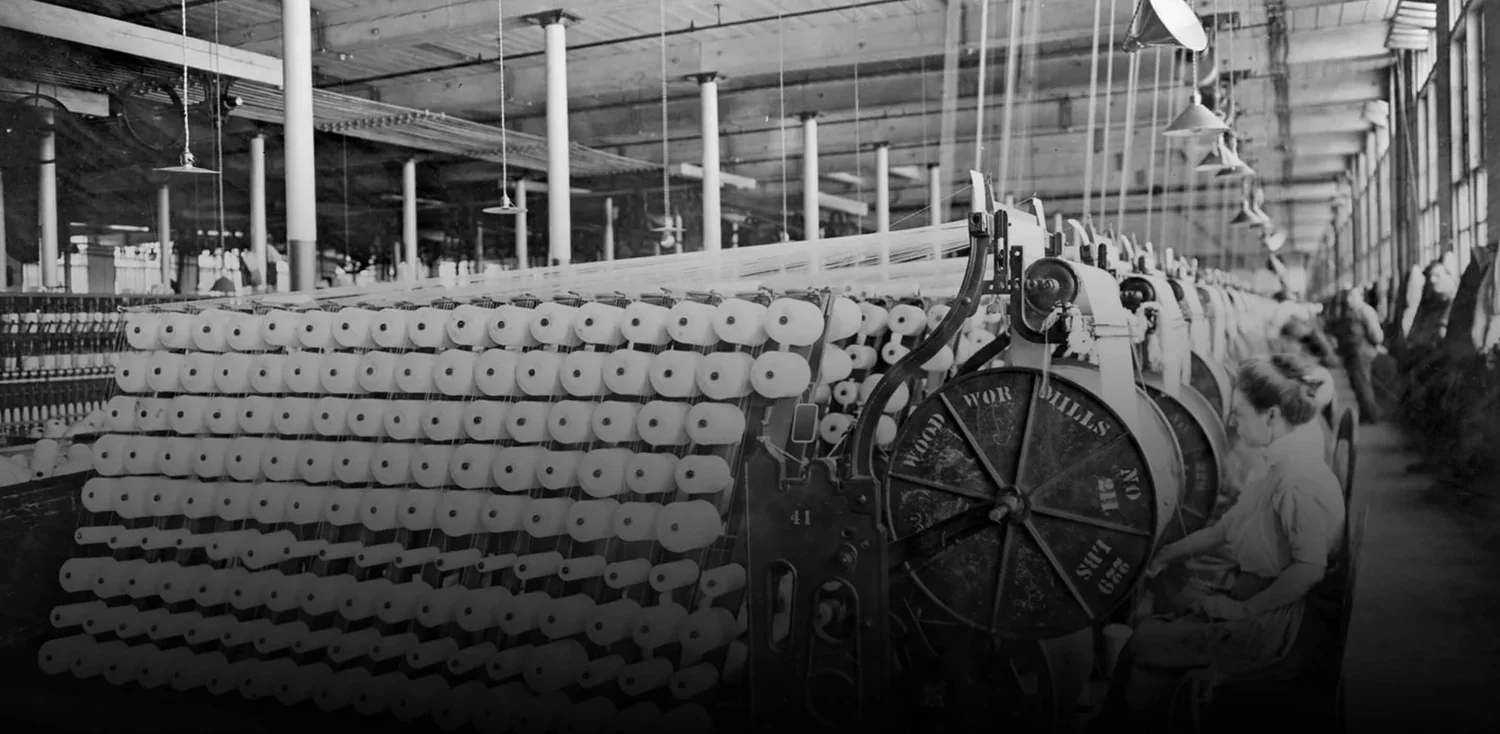

Introduction

Many textile mills still vent low-pressure exhaust to atmosphere—those big white “steam clouds.” That’s avoidable energy loss. A steam thermocompressor captures that flash steam & recompresses it back into the process. Below is a practical, numbers-first walkthrough of how one textile plant eliminated visible venting, cut boiler fuel, & simplified its steam & condensate loop.

The problem: visible vent = visible loss

Vented flash steam is fuel you already paid for, escaping your site. In a typical textile plant, low-pressure (<2 bar) exhaust from washers/dryers was released directly to atmosphere—pure waste that also disturbed pressure balance & humidity around the line.

A Baelz textile note calls this “an avoidable waste of energy,” confirming many plants vent low-pressure steam unnecessarily.

The fix: install a thermocompressor on the vent

Instead of dumping 2 bar vapor, the mill fitted a steam jet thermocompressor to suction that vapor & compress it using a small motive-steam flow (3 bar). The device then regulates the mixed steam back to the consumer setpoint (3 bar), converting a vent into a heat recovery system that feeds your heating systems.

Result: the plant no longer emits direct exhaust steam.

Simple science: how the ejector works

High-pressure motive steam accelerates through the nozzle (Variable nozzle design).

That jet creates suction, entraining the low-pressure flash steam from the vent.

In the diffuser & nozzle section, velocity is turned back into pressure—delivering usable mixed steam at ~3 barg.

That’s the thermocompressor working principle: a compact vapor compressor with no rotating equipment.

The key number: 1 kg in = 1 kg avoided

Every kilogram of 2 bar steam recovered by the jet pump reduces the demand for 3 bar steam by 1 kg. That 1:1 displacement is why thermocompression is powerful for saving energy—you immediately cut fresh boiler steam.

What changed on the ground

Before: 3 barg consumers ran entirely from fresh boiler steam.

After: a Jetomat mixes 3 barg motive steam with 2 barg suction & controls the mixture to 3 barg—so consumers see the same pressure, but the boiler now supplies much less fresh steam overall.

Tangible plant-level results

No more steam clouds: “The entire plant no longer emits direct exhaust steam.”

Lower fuel: every recovered kg reduces firing. In similar textile dryer retrofits (valves → ejectors), mills saw ≈15% steam savings (1-row line) & ≈20% on larger, 3-row lines—plus trap removals.

Water & chemicals down: keeping condensate/flash in-loop lowers make-up water & treatment demand (documented strongly in paper/corrugated; principle holds in textiles).

Hidden win: better heat transfer & fabric quality

Higher internal steam velocity thins the steam condensate film on cylinders, improving heat transfer solutions (hotter, more uniform drum surface for the same header pressure). Plants consistently report more uniform drying & the ability to nudge line speed upward after switching to ejector-based steam equipment.

Fewer traps, simpler loop

Thermocompressors form a condensate & flash steam recovery system that continuously entrains vapor. In many dryer sections, drum-level steam traps were removed or drastically reduced after installing ejectors—cutting maintenance & leak points. (A textile 1-row case eliminated post-drum traps entirely.)

Practical integration tips

Thermocompressor design: match motive/suction/mixed pressures & the expected vent rate; size for daily extremes.

Controls: regulate mixed pressure or downstream temperature; a standard control valve on the motive line is enough.

Piping: keep suction run short, avoid sharp restrictions; provide proper drainage. Often you can simplify or avoid a separate steam separator because the flash steam recovery system is now integral.

Why not just use a PRV?

A PRV throttles—it doesn’t recycle. The exergy lost in throttling is gone, & you still vent flash elsewhere. A thermo compressor (Jetomat) converts that vent to useful mixed steam. That’s the difference between dropping pressure & re-using it. (In other sectors, right-sized ejectors have paid back in ~1.7 months; textiles with strong vent sources can see similarly fast returns.)

Conclusion

Thermocompression turns an atmospheric vent into a controlled heat recovery system. In this textile mill, a Jetomat steam jet compressor captured low-pressure exhaust, stopped the steam clouds, & cut boiler fuel—while improving heat transfer & simplifying the steam & condensate loop. Start where the plume is biggest: measure the vent, size the ejector, pipe a short suction, & regulate mixed pressure. From there, scale across washers, dryers, & other users.

Next Steps

Walk-through the line; identify the biggest vent.

Log pressures/flows; build a quick mass/energy balance.

Fit a pilot steam jet thermocompressor, verify the 1:1 kg displacement & fuel drop.

Roll out to remaining vents for cumulative saving energy across the plant.